Grade 5 titanium alloy, also known as Ti6Al4V, Ti-6Al-4V or Ti 6-4titanium alloy, is the most commonly used alloy. It has excellent specific strength, excellent corrosion resistance and fracture toughness, as well as good weldability and ability to withstand extreme temperatures, and can be strengthened by heat treatment. The alloy was originally developed for the aerospace market and is widely used in aerospace structural components. Because of its very good biocompatibility, it is also widely recognized in the medical industry. Typical applications include aero-engine components, fuselage components, marine equipment, offshore oil and gas equipment, power generation, chemical industry, automotive moving parts, medical equipment, surgical implants, sports equipment.

Titanium Sheet Grade 5 has excellent corrosion resistance, small density, high specific strength and good toughness and weldability. It has been successfully applied in aerospace, petrochemical, shipbuilding, automotive, pharmaceutical and other sectors.

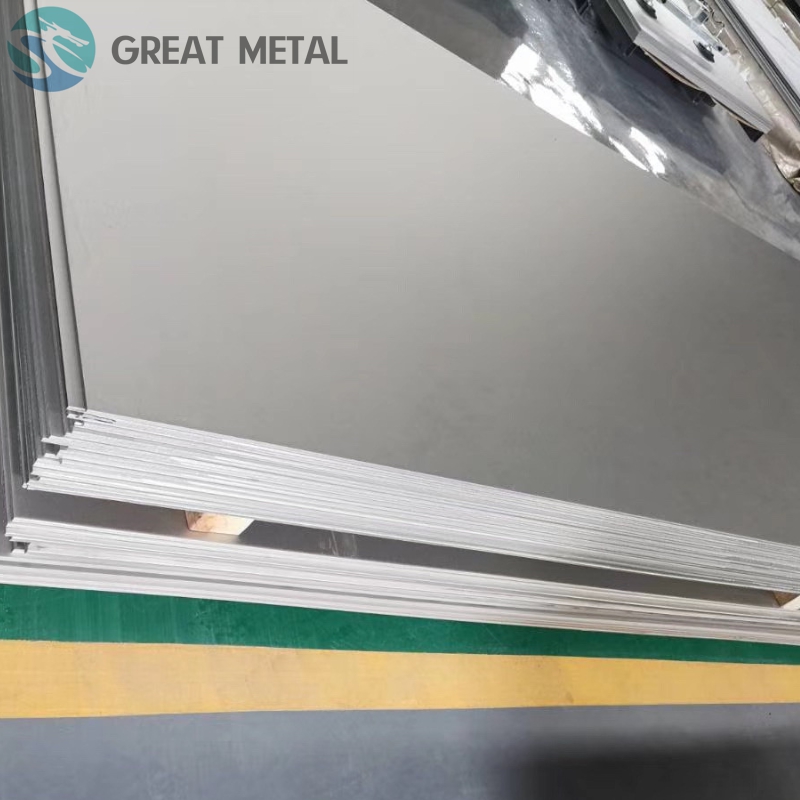

Standard: ASTM B265,ASMESB265,AMS4911,ASTM F136, ISO5832-3,

Grade: Gr5(TC4)

Thickness: 0.8mm~60mm

Width: 1000-2000mm

Length: 6000mm

Technique: Hot Rolled & Cold Rolled

Condition: M R & M m Y

Application: Mainly applied to aviation, shipping, chemical and industrial equipent manufacturing, medical, automobile as well sports.

Characteristics

- Low density and high specific strength.

- Excellent corrosion resistance.

- Good heat resistance.

- Good low temperature resistance.

- Strong anti-damping performance.

- Non-magnetic, non-toxic.

- Tensile strength is close to its yield strength.

- The thermal conductivity is small.

- Low modulus of elasticity.

- Strong suction performance.